Superbinder-200F Perfect Binder

Superbinder-200F is a newly upgraded four-clamp perfect binder with max. mechanical speed up to 2000 cycles per hour. It employs the modern industrial design, and new upgrades on the critical stations for quick changeover and superior binding quality. Superbinder-200F is an ideal solution to fulfill your every demand for both digital and offset production with quick return on investment.

Outstanding Features:

Quick Setup and Changeover: Thanks to the automatic adjustments on the critical working stations, quick setup and changeover can be completed in a few minutes.

High Production Efficiency: Binding production speed can reach up to 2000 cycles/hour, together with best-in-class binding quality for both digital and offset production.

Outstanding Binding Quality: The optimized dual-axis cover scoring station and the special designed nipping station ensure the strong and durable binds with sharp corners.

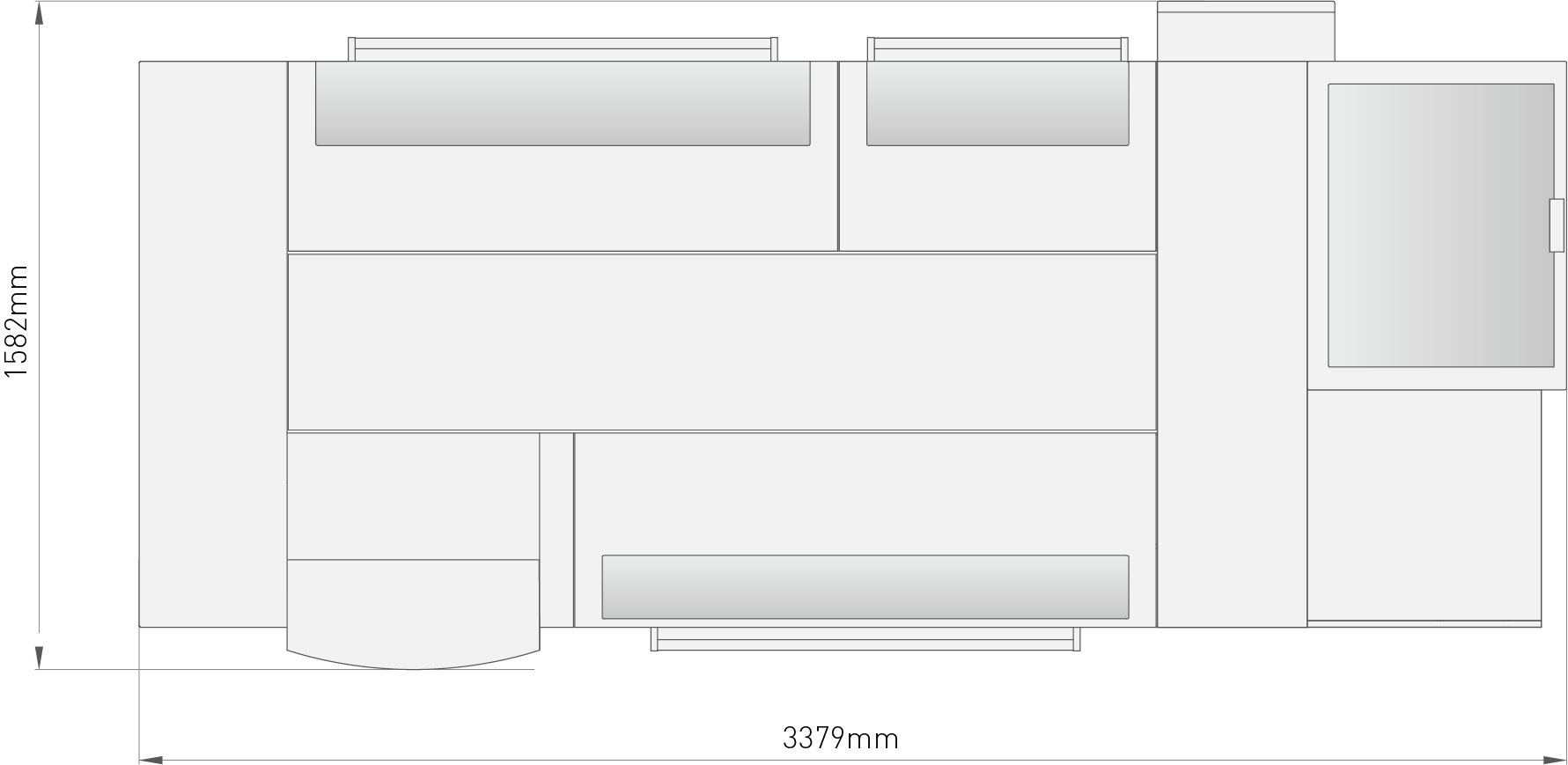

Product layout:

|

Touch Screen The icon-based Schneider touch screen provides easy operation and automated adjustment on the critical working stations, which also serves as the fault monitor.

|

|

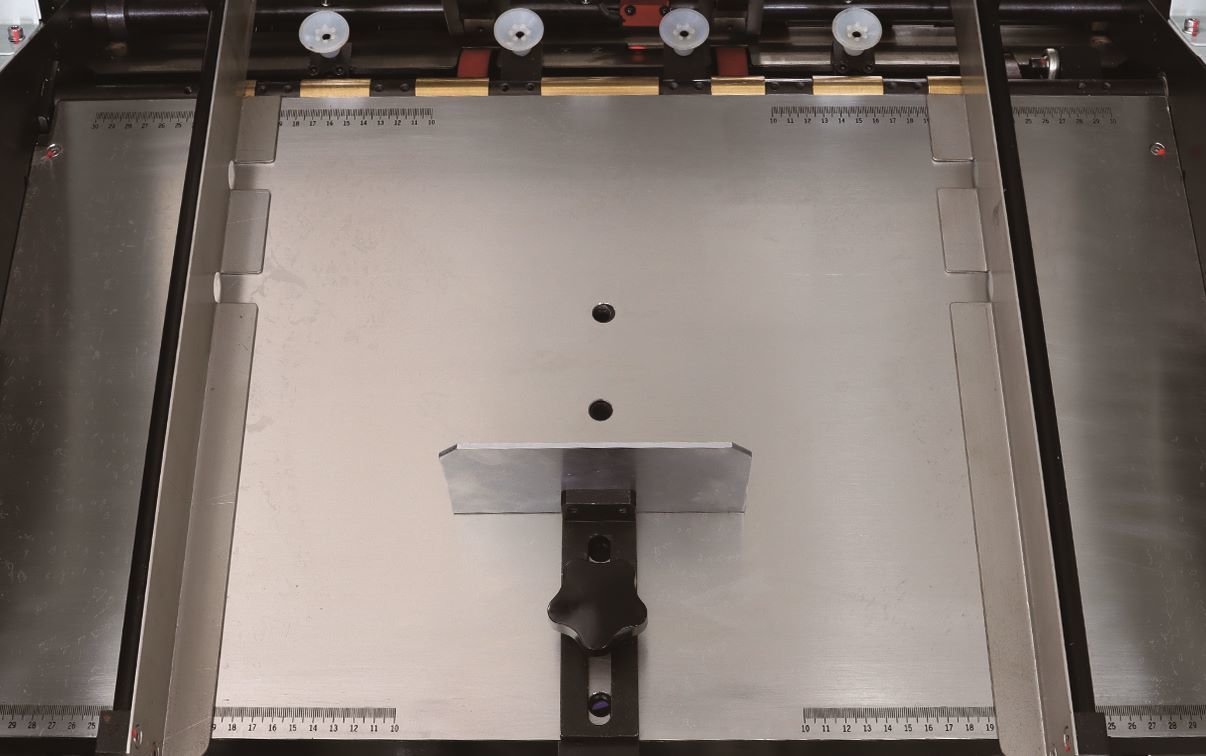

Book Feeding Station

The opening width adjustment of book clamps is fully automated. Book feeding station height is adjustable. |

|

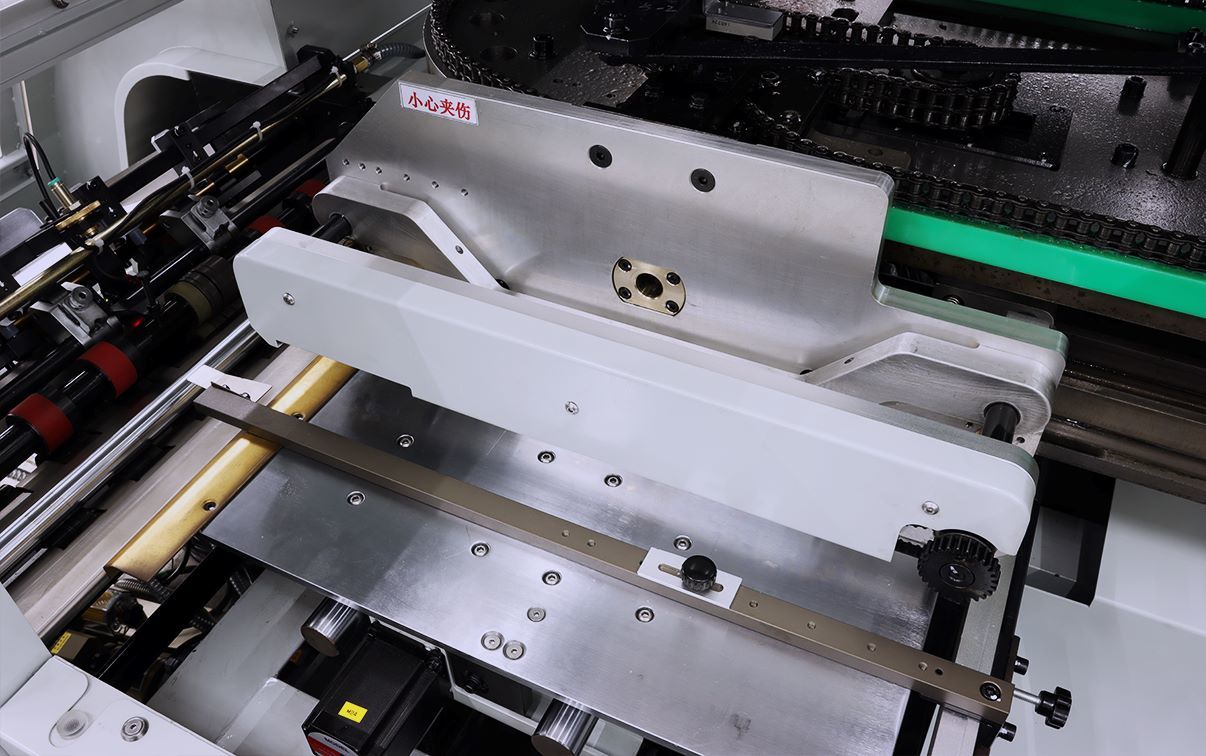

Milling System

Spine milling, notching, and brushing. The opening width of milling plates is automatically adjusted. Operator can easily enable and disable the milling as needed.

|

|

Gluing Station

The independent side gluing station and spine gluing station ensure superior glue application for optimal binding quality. The opening width of side gluing disc is automatically adjusted according to the book thickness. The length of spine glue is regulated by a ruler. |

|

Cover Feeder

The cover scoring opening is automatically adjusted. Cover scoring adopts MISUMI screw rod and linear guide way for higher precision adjustment and perfect scoring lines. Cover jam, miss-feed and double-feed can be accurately detected. |

|

Nipping Station

The opening width of nipping plates is automatically adjusted. Nipping height and nipping pressure allow fine adjustment for perfectly-shaped book spines. |

|

Machine Model |

Superbinder-200F |

|

No. of Clamps |

4 |

|

Max. Mechanical Speed |

2000 c/h |

|

Book Block Length (a) |

140-450mm |

|

Book Block Width (b) |

120-270mm |

|

Book Block Thickness (c) |

3-50mm |

|

Cover Length (d) |

140-450mm |

|

Cover Width (e) |

240-620mm |

|

Machine Weight |

1900kg |