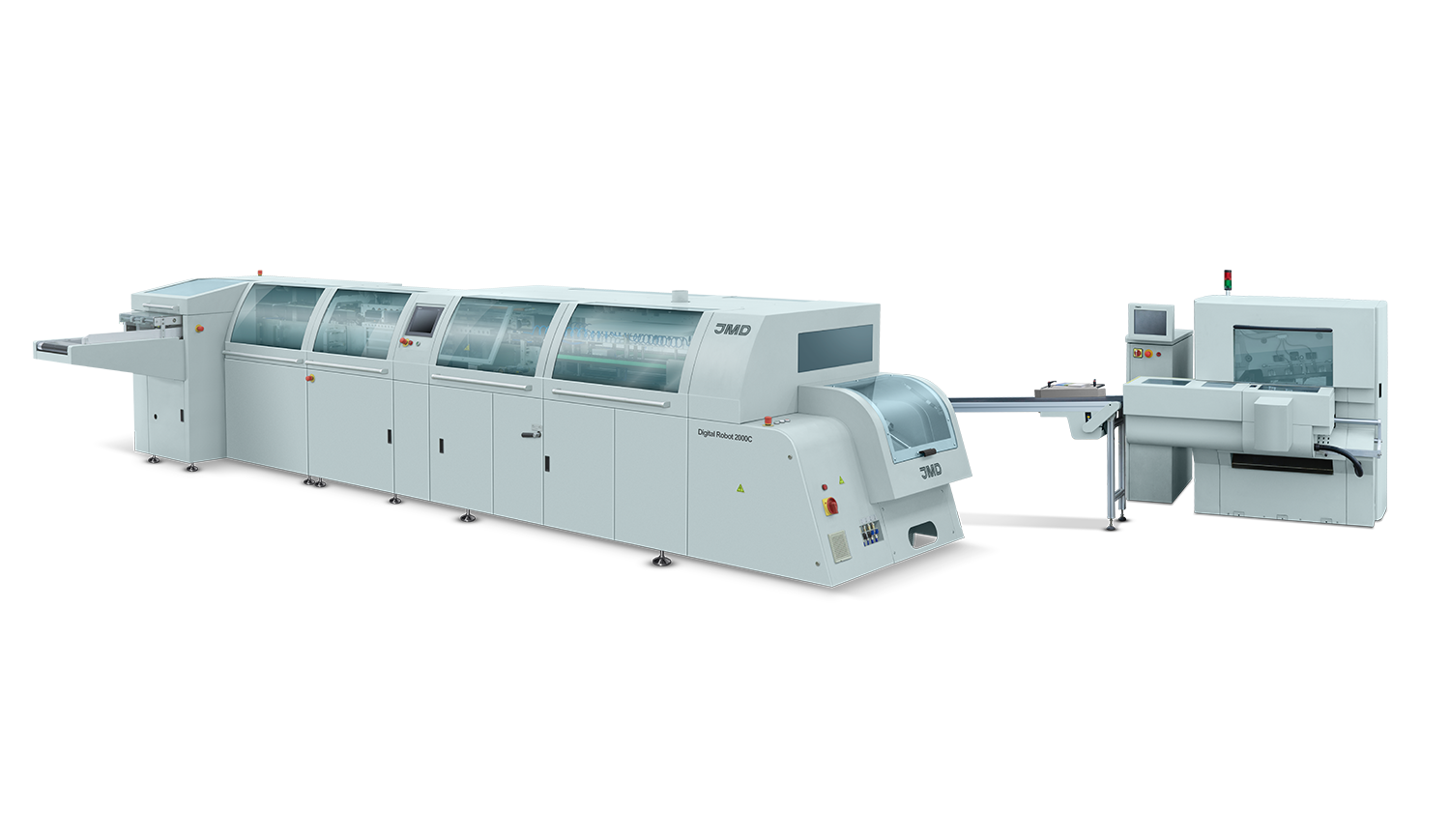

Digtal Robot 2000C

Smart Binding Solution for Effcient In-Line Production

Digital Robot 2000C is designed for the growing demand of efficient in-line production from digital printer to perfect bound books. It features new level of automation, and provides smart connectivity to various types of digital printer and paper processing system.

It is capable to in-line connect with HP, Kodak, Canon, Ricoh and other different brands of digital printer to achieve an integrated production line, which offers a seamless workflow with maximum variability and flexibility for on-demand production.

Outstanding Features:

Seamless and Touchless Workflow: It is capable of seamless integrating with upstream digital printers to achieve a fully automated digital production line with improved system efficiencies.

Fast Automatic Changeover: Automatic job changeover can be accurately completed down to 15s for book thickness and book formats change at the fastest speed.

Optional PUR Gluing System: User-oriented moveable glue tank design allows changeover between EVA and PUR glue application system in just minutes.

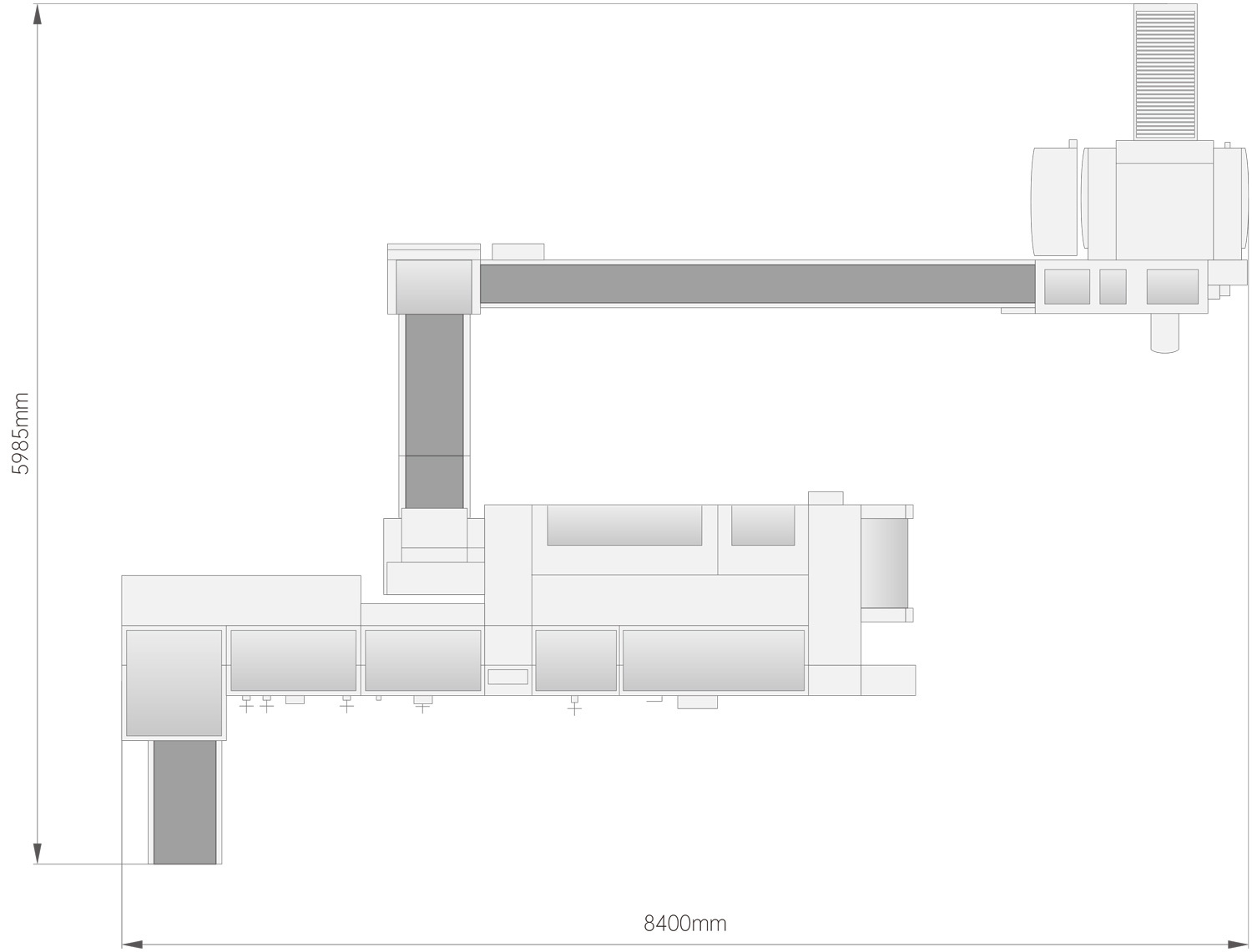

Machine Layout:

|

Vertical Turning Module

The vertical turning module is to automatically feed the book blocks from upstream, and turn the book blocks from vertical into lay-flat. All setups are fully automated according to the book block thickness and format. |

|

Robot Arm

Smart robot arm controlled by servo motor can automatically and precisely feed the book blocks. |

|

Central Control System

Icon-based touch screen serves as a central control and monitor system of all modules. 99 jobs can be stored and accessed again for for repeat jobs. |

|

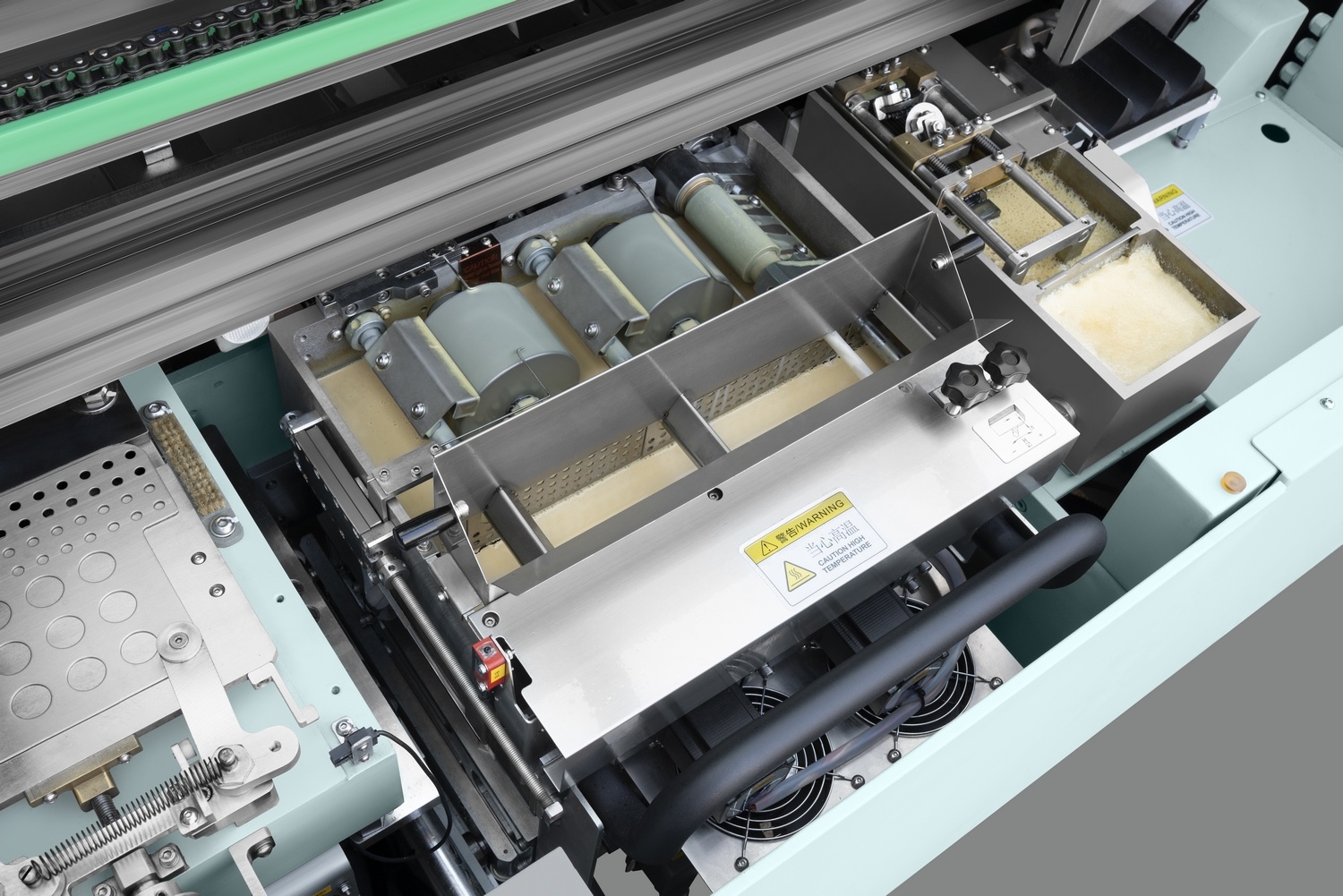

Spine Gluing Station

The spine glue length and thickness are adjusted automatically and accurately. Interchangeable gluing system allows easy changeover between EVA and PUR. Side Gluing Station The side gluing discs are adjusted automatically according to the book thickness. |

|

Cover Feeding Station

The special in-feed design from the bottom enables that cover sheets can be added on the fly without stopping the production. The side gauges of cover feeding station and position of cover scoring wheels are automatically adjusted according to the input data. |

|

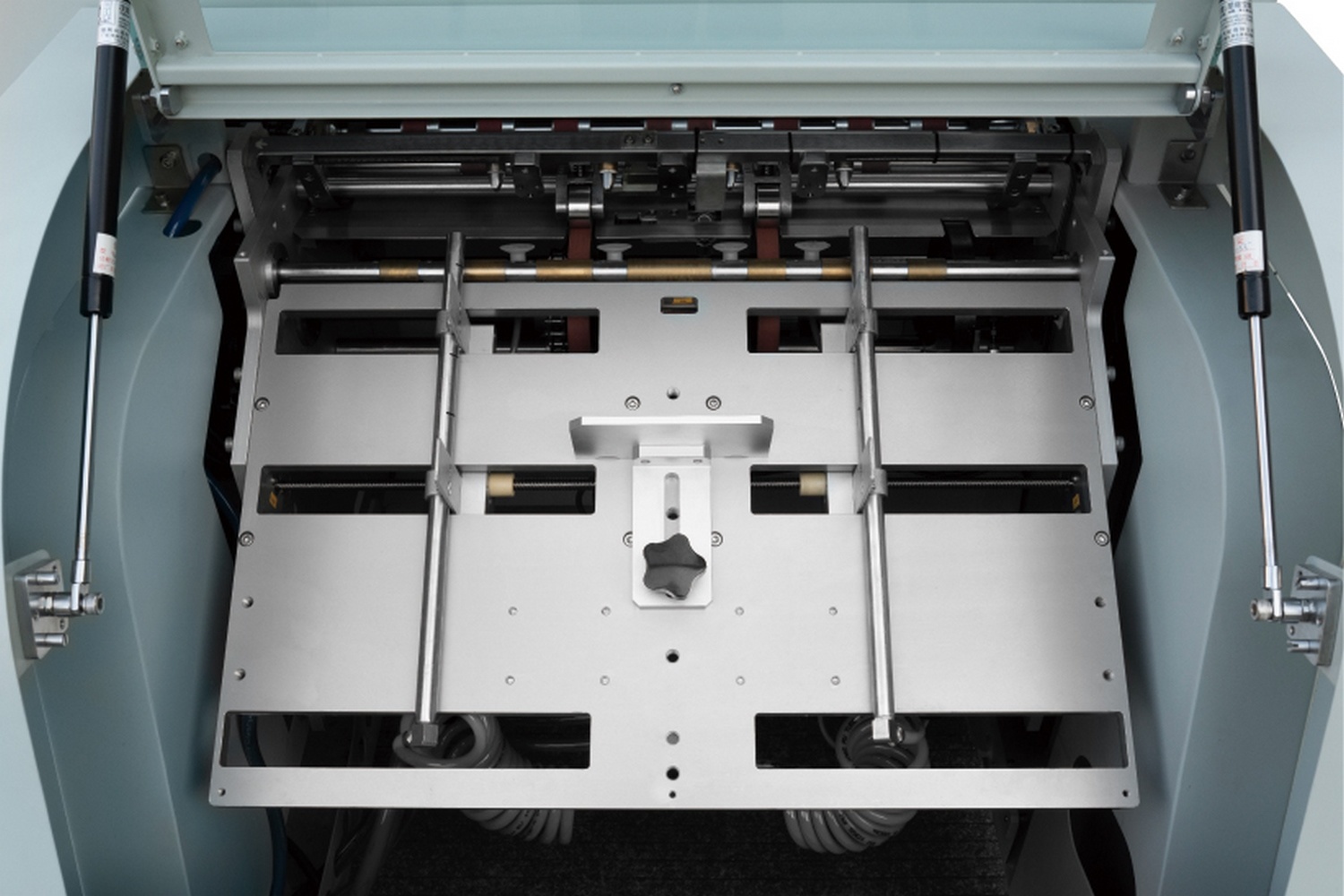

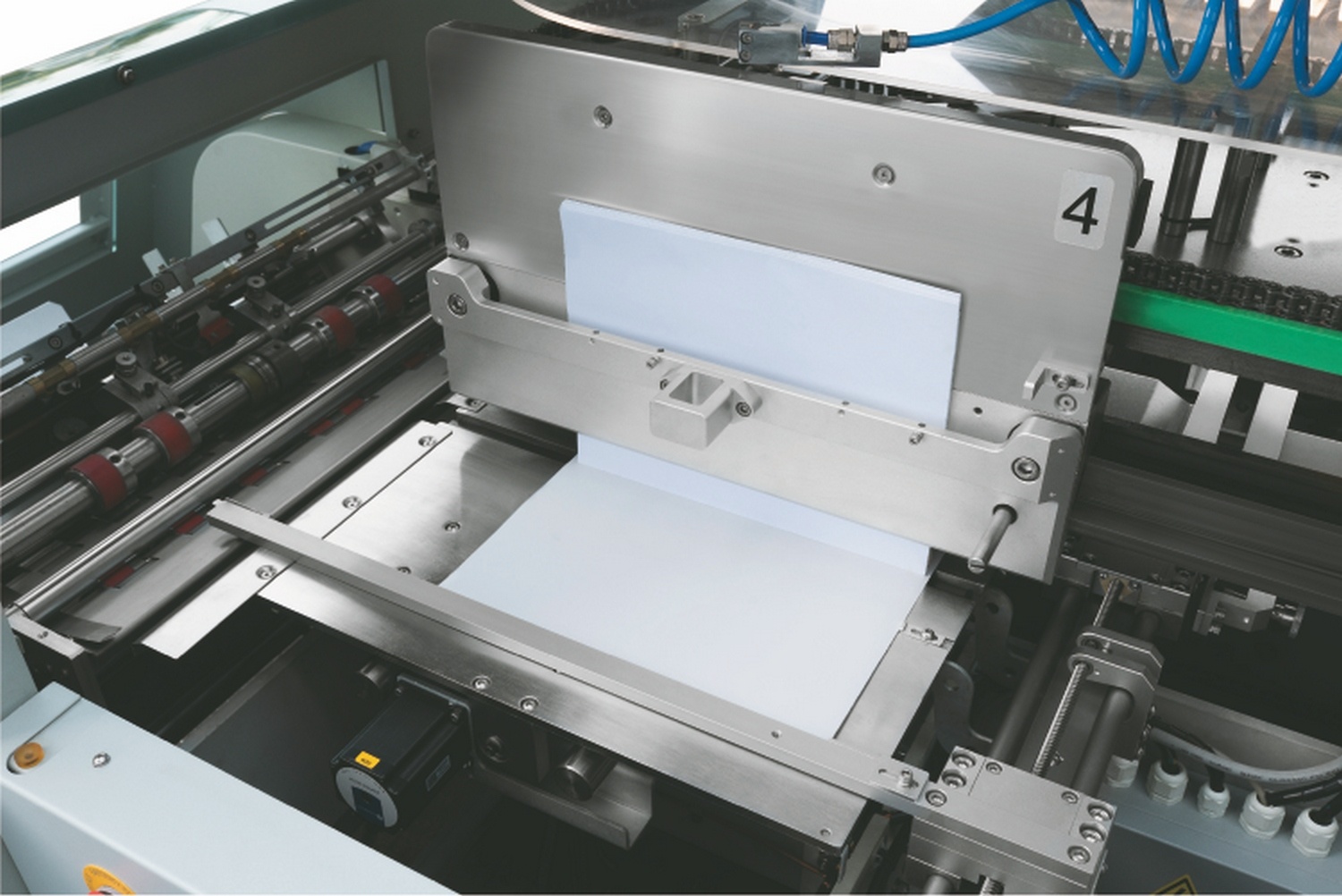

Nipping Station

Thanks to the strong and rigid nipping mechanism, covers can be precisely and firmly nipped with the book blocks to obtain perfectly-shaped book spines. The opening width of nipping plates and side gauges are automatically adjusted. |

|

Machine Model |

Digital Robot 2000C |

|

No. of Clamps |

4 |

|

Max. Mechanical Speed |

1600 c/h |

|

Book Block Length (a) |

140-320mm |

|

Book Block Width (b) |

120-270mm |

|

Book Block Thickness (c) |

3-50mm |

|

Cover Length (d) |

140-450mm |

|

Cover Width (e) |

250-590mm |